|

S E A N E T ™

Please use our A-Z to navigate this site or return HOME

OCEAN CONDITIONER - This vessel is designed to operate in fleets to target ocean waste cost effectively. There is nothing like it in existence today, though other ideas for trapping marine litter and sargassum are being developed, such as that of Boyan Slat and the Seabin (both plastic). SeaVax machines are made more cost effective in operational terms with AmphiMax versatility - that slashes the cost of production and servicing by using a portable dock for assembly, launch and servicing. This assumes islanders would be operating their own cleaners, with in-house (presumably, small scale) facilities to handle the harvested product. Even so, a SeaVax-Calypso could conceivably capture up to 500 tons a day (hydrogen enhanced). That's a lot of seaweed for one island to deal with. A better arrangement might be a Sargassum Cooperative. But there is no such thing as a free lunch & money talks. The project will have to be fully funded somehow - or further development will not take place. Expressions of interest to: Cleaner Ocean Foundation.

In order to make SeaVax ocean cleaning machines more effective, in addition to remotely operated (drone) control, it would be an advantage to network fleets of autonomous drones of SeaVax sargassum machines, so that they may communicate by data sharing, and also for effective fleet control, such as to form a virtual net, to scoop up sargassum blooms, as the vast floating chains head to the Caribbean Islands, and other locations unfortunate enough to have their sandy shores choked on a regular basis. We call the drone navigation system SeaNet.

We would suggest such development, for any autonomous machines employed in this capacity.

NASA and other satellite operators are already tracking sargassum blooms, most especially in the Equatorial Atlantic, as it heads to the Mexican Riviera, in Quintana Roo.

Satellite based command and control can be used to to plan missions that may be subsequently modified by live incoming data, to include feedback data from reading the oceans for chemical, biological and macroalgae makeup to let the operation centres, and forward mission planners know how accurately they are reading the oceans and how much sargassum has been harvested.

SEANET GEODATA SHARE & COORDINATION

SeaNet

is designed to be accessible to other compatible vessels in

the race to clean choking seaweed blooms from the oceans.

The system may be adapted to accommodate other vessel

formats such as surface skimmers, and even collection systems

like booms. The idea being to share information between

operators so that when one area has being cleaned adequately,

assets may be re-deployed more effectively in other lesser

patrolled regions, where sargassum is still prevalent.

OCEAN TRANSFER - In this diagram we see a 180 x 28 meter Handysize bulk carrier (drawn to scale), and five SeaVax Sargasso ships docking to unload their sargassum haul. If one Handymax can handle around 50,000 tons of harvested seaweed, it would then take 66 SeaVax transfers (in multiples of five as shown) @ 1,000 tons per couple, to fill up one cargo ship. A Handymax would cruise between SeaVax fleets, emptying them in sequence, or as requested by the SeaVax vessels themselves - to make a virtual conveyor belt to land as part of a SeaNet system.

Assuming 24 million tons of sargassum per year as the target yield. We would suggest a fleet of 10 Handysize bulk carriers, aiming for docking 10 SeaVax Sargasso's 2 or 3 times a day. Each complement of coupled offloads could (@ 2,000 tons each) handle between 4 - 6,000 tons of sargassum per day. Multiplied by 10 ships, equals 40-60,000 tons per operational day - or around 10 million tons in 200 operational days per year. Meaning, that to cope with 24M tons, we'd be looking at operating 25 Handysize bulk carriers operating in the equatorial Atlantic, to cope with the present state of emergency.

That would of course mean clean beaches in the Caribbean Sea. If that could be achieved. Funding being the main obstacle to overcome. This frequency of operations may be reduced, by operating SeaVax Calypso machines in the Caribbean Sea. We'd suggest that the stakeholders may want to collaborate on a study, as the first port of call. To decide on a workable strategy, with quotes, etc. Followed by a proof of concept machine at a small scale, and then a pre-production prototype at 'Calypso' scale, or smaller. Budget dependent.

DOCKING PROCEDURE - The docking couplings and method of transfer are not shown or explained here in any detail for legal reasons. Having said that, we can show you the basic principles. The SeaVax and SargassoMax (a converted bulk carrier) on the left are shown together with the hold of the bulk carrier about one third full with the SargassoMax floating high in the water. As the cargo hold fills up with sargassum the ship displaces more water and sinks deeper into the seawater. A special coupling and transfer technique is needed to make this work. The same system will work just as effectively when SeaVax is transferring its cargo in harbours, ports and rivers, or to factories located conveniently on beaches - using Amphimax machines.

Ideally, the Handysize bulk carrier diesels, should be converted to run on methanol or ammonia. Assuming, purchases of older vessels that have reached the end of their ordinary working life. Another way to make second user ships zero emission, would be to use ancillary electric pod thrusters, and decks loaded with solar panels. Agreed, that this would raise the overall cost of ocean sweeping. But then, the situation may eventually worsen, to a global plague. In which case, (presumably) governments would need to respond rather more urgently than at present. Or we'd not only have coastal tourism (economy) issues, but also a major food security emergency - demanding international relief efforts. Design and Copyright © drawings. Cleaner Ocean Foundation Limited, September 2022. You do not need permission to use these diagrams for personal research or educational projects. All other rights are reserved.

SeaVax machines may stay out at sea for prolonged periods, working with converted HandyMax bulk carriers, as factory ships, to process the harvested sargassum catch. Alternatively, the bulk carriers may return to designated ports for offloading of their cash crops. But that would be an advanced level of development, some years down the line, with profits from previous year's cash crops to invest. At the moment it is a loss making situation.

THE BATTLE LOST - What is brown and stinks? You might argue the G20's climate change policies : ) Sargassum is proof that the major players have fouled up big time. Once the brown peril hits the beaches, you've already lost the battle. You need to take the fight out to sea to turn the tide. By the time we have climate reversal, all these local business will probably be bust. If you believe otherwise, watch out for FLOP 27. We predict it will be more hot air and little action, as with the past 20 years of blah, blah, blah. Consequently, most Caribbean islanders would agree that sargassum is here to stay. Acceptance is key to dealing with it. And JCB's and other mechanical beach cleaners are not the way. They damage the beaches and mine the sand with the sargassum. Disposal is also a major problem, with few proper treatment plants, and burying the problem, likely to do more long term ecological damage.

MEXICAN NAVY - Because of the State of Emergency on the Caribbean Sea beaches of Quintana Roo, the Mexican Navy was seconded to haul in up to 600 tons of sargassum. But that barely scratched the surface of the problem. Normal ships use heavy diesel bunker fuels and are not specially equipped to catch floating sargassum, raising the carbon footprint - where the ideal is being carbon neutral. In addition, using manual labor to undertake such a task is not cost effective, compared to fleets of automated and autonomous drones.

Please note that 'automated' refers to the ability of a machine to harvest and sort sargassum from plastic without human assistance, while 'autonomous' refers to navigation in the first instance, and energy captured from nature in the second instance. In this case solar power. The good news is that solar panels are now a lot cheaper and more efficient than say 10 years ago.

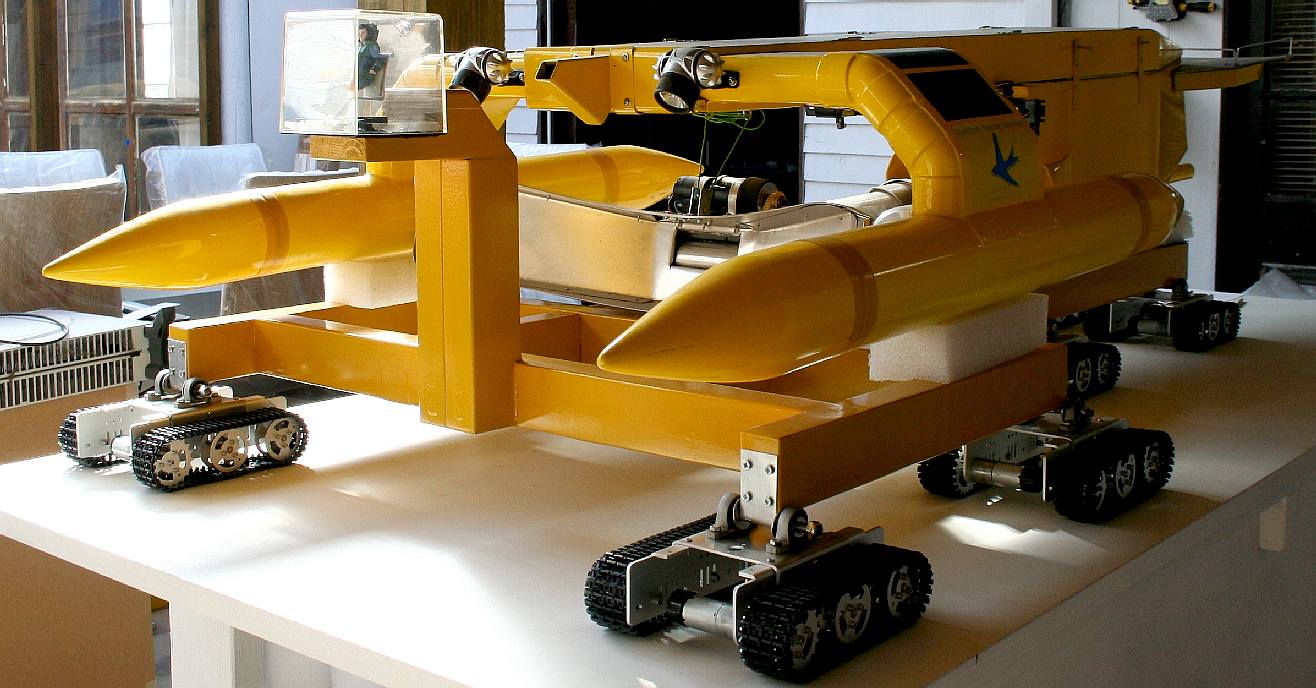

OCEAN CLEANING SUPPORT RIG - The SeaVax ocean plastic cleaning vessel is seen here on an AmphiMax beach launcher in 1/20th scale for (proof of concept) testing in the Cleaner Ocean Foundation's water basin. Copyright © photograph 25 June 2018 Cleaner Ocean Foundation. All rights reserved. In 2021, the AmphiMax successfully transported the SeaVax model, including proving the concept of the variable track steering system. NASA use steer-able tracks on their rocket transporters. We needed to keep CAPEX down.

NOTE: As the cost of operating large blue water fleets would involve considerable investment. We would suggest not beginning in that way, because of the outlay. We would suggest beginning such cleaning programmes more locally in the Caribbean Sea, using smaller sweeping machines like the SeaVax-Calypso, working in tandem with an amphibious landing craft, like the AmphiMax-Calypso. The initial investment would thus be containable, making such a system affordable. Especially when compared to the enormous and damaging cost of beach cleaning, and naval patrols. And please note, these are examples, as a baseline for other projects to build their ideas, and to inspire other development teams as appropriate.

LINKS & REFERENCE

http://www

This website is provided on a free basis as a public information service. Copyright © Cleaner Oceans Foundation Ltd (COFL) (Company No: 4674774) 2022. Solar Studios, BN271RF, United Kingdom. COFL is a charity without share capital. The names Amphimax™ RiverVax™ SeaNet™ and SeaVax™ are trademarks.

|