|

MAST & HYDRAULICS

ABOUT - CLIMATE CHANGE - CONTACTS - CROWDFUNDING - DONATE - FOUNDATION - OCEAN CLEANUP - HOME - A-Z INDEX

DONOR VEHICLE - This is the basic Ford Transit, as themed for awareness logistical support in 2018 by marine biologist, Emily Hoad. Copyright © photograph Cleaner Ocean Foundation Ltd. All rights reserved, save for educational and research purposes.

A vehicle can be converted into plant by making machinery for generation, welding, pumps and other equipment permanently fitted. This experimental eco energy harvesting rig was fitted to a standard Ford Transit van. On this page you can see how we fitted the moveable mast using two men and an engine hoist. You can also see what it takes to beef up the structure to take the overhead loads.

INTERNAL BRACING - The start of the internal frames that will carry twin hydraulic double acting cylinders to power the mast up and down. In this picture we see a timber floor pad and uprights before the steel bracing is added. Copyright © photograph 16 May 2019 Cleaner Ocean Foundation Ltd. All rights reserved, save for educational and research purposes.

REINFORCING - An early CAD drawing of the proposed conversion of a Ford Transit to an energy harvesting experimental rig in connection with the SeaVax and RiverVax concepts. Copyright © diagram March 12 2019. All rights reserved, Cleaner Ocean Foundation Ltd.

We'll need to build temporary scaffolding with substantial walking boards to be able to fit the wind turbines and upper hydraulic rams, hoses and control sensors while working over the bonnet and windscreen. Note the large cushions we are using as pads against the delicate screen and roof sections.

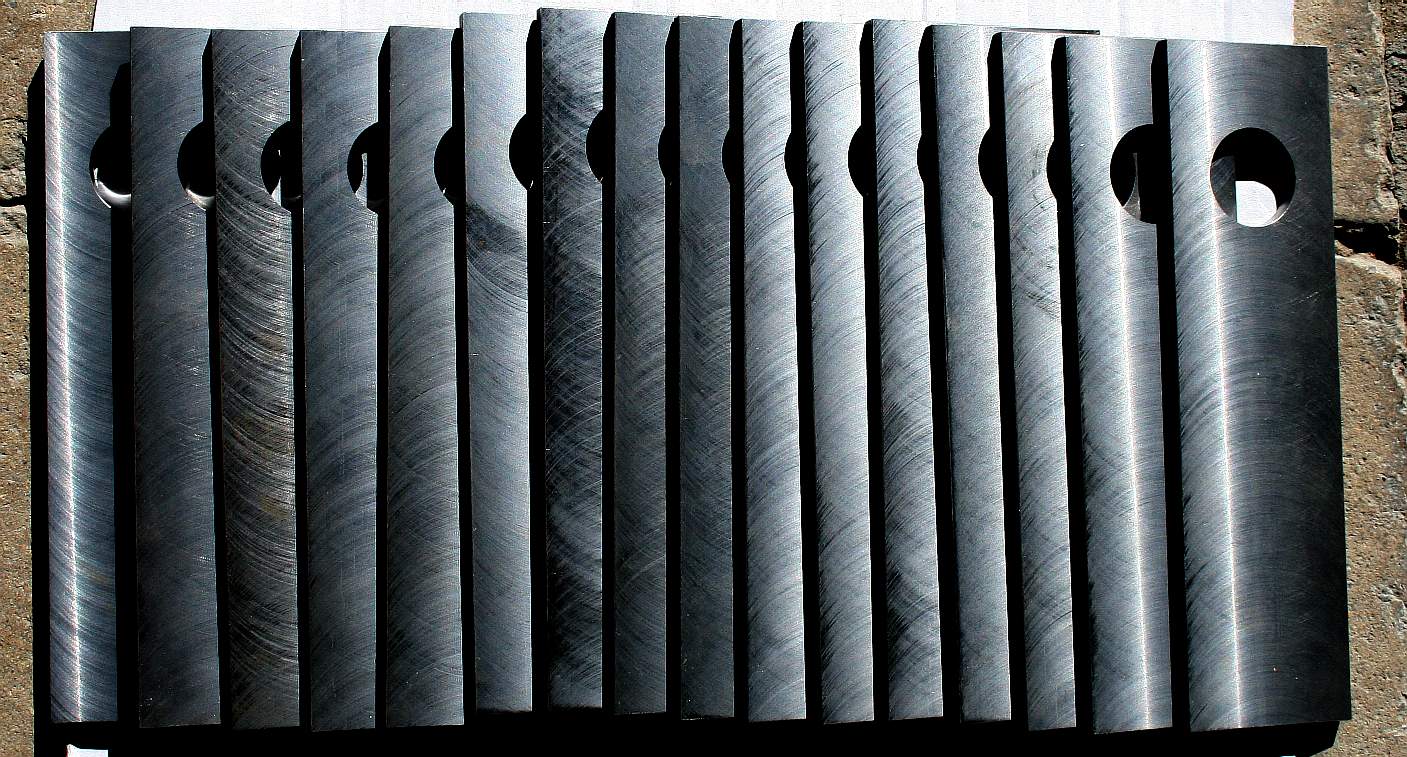

HINGE PLATES - We needed 16 precision engineered hinge plates, bored out to 26mm. These are to be welded to the mast ladder sections so that the four ends are in alignment. Copyright © photographs May 16 2019. All rights reserved, Cleaner Ocean Foundation Ltd.

MAST LADDERS - Having marked out the positions of the hinge plates, they were tack welded in place. The reinforcing bars needed to be precisely cut as spacers to ensure that the hinge centers were at 500mm and that the length of each individual tube was the same. Copyright © photographs May 16 2019. All rights reserved, Cleaner Ocean Foundation Ltd.

BIO-ENGINEER - Helping with the construction of the mast frames, Lolita D'Ortona is a student from Belgium. She checked the position of a bracket that is welded in pairs to make a pin/pad for the hydraulic rams. These couplings take most of the loads fed into the mast when raising the structure. Most of Lolita's work has been on design of the software that will control the experimental rig. Copyright © photographs May 16 2019. All rights reserved, Cleaner Ocean Foundation Ltd.

HYDRAULIC PADS - We needed to make pad mountings for the rams that would raise and lower the mast. These double acting cylinders had 25mm ends. We also needed to make the pins, as nobody in England appears to make 25mm bolts, or supply pins for these hydraulic rams. They are always custom made. In this case we made the holes with a tungsten cutter and plenty of lubricating fluid. Copyright photograph © 12-05-19 Cleaner Ocean Foundation Ltd, all rights reserved.

TACK WELDS - A close up of the tacks that allowed assembly prior to full-on structural welds. The mast ends needed to be a good fit to limit lateral movement in high winds, but still able to swing upright without putting too much of a load on the hydraulic actuators. Copyright photograph © 12-05-19 Cleaner Ocean Foundation Ltd, all rights reserved.

TEST FIT 1 - The lower mast arm was test fitted with roof cushions in place and using an engine hoist as a safety. The fit was near perfect. The arm was removed for welding to be completed and for painting. Copyright photograph © 12-05-19 Cleaner Ocean Foundation Ltd, all rights reserved.

TEST FIT 2 - The upper mast arm was test fitted using the same method. Again the fit was near perfect. We breathed a sigh of relief. The other (working) end at the top of the mast still in the workshop also has to fit to the same standard. Copyright photograph © 12-05-19 Cleaner Ocean Foundation Ltd, all rights reserved.

PRECISION ENGINEERING - Picross offer a world class development service from prototype to production. This includes the latest CNC turning and machining centers, precision Tig welding, vacuum leak testing, bar-coded bespoke labeling and powder coating, all at competitive prices.

Picross Precision Engineering Co Ltd. 16-18 Lister Road, Eastbourne, BN23 6PU, UK. Tel: 01323 507322 Email: sales@picross-eng.com

FLOWFIT

- From Cylinders to Hand Pumps and Filtration components to Motors, Flowfit Hydraulics are one of the industry leaders in the provision of

effective and reliable hydraulic components.

Parys Road, Ludlow Business Park,

Ludlow, Shropshire,

SY8 1XY.

WELDING - Our TIG, MIG and plasma cutting equipment was supplied by: R-Tech Welding Equipment Ltd Unit G1 & G2 Innsworth Technology Park, Innsworth Lane Gloucester UK. GL3 1DL. Tel: 01452 733933

LINKS & REFERENCE

https://www.gembloux.uliege.be/ https://www.picross-eng.com/ https://www.parkersteel.co.uk/ https://www.r-techwelding.co.uk/ https://web.stanford.edu/group/efmh/winds/global_winds.html https://www.quora.com/Why-does-winds-velocity-increase-when-height-increases

THIS IS WHY WE CARE - This polar bear is a magnificent animal that is at the mercy of human activity. Humans are for the most part unaware of the harm their fast-lane lifestyles are causing burning fossil fuels that cause climate change - and in turn melting ice caps and acid oceans. We aim to change that by doing all we can to promote ocean literacy to help reduce our plastic and carbon footprints.

This website is provided on a free basis as a public information service. Copyright © Cleaner Oceans Foundation Ltd (COFL) (Company No: 4674774) 2019. Solar Studios, BN271RF, United Kingdom. COFL is a charity without share capital. The names Amphimax™ RiverVax™ and SeaVax™ are trademarks.

|